All procedures are controlled by HMI & PLC, all parameters can be revised in HMI with easy operation

– State standard Q235B Profile steel are used for block mould frame.

– State standard LY12 aluminum is used for steam chamber, thickness 5mm

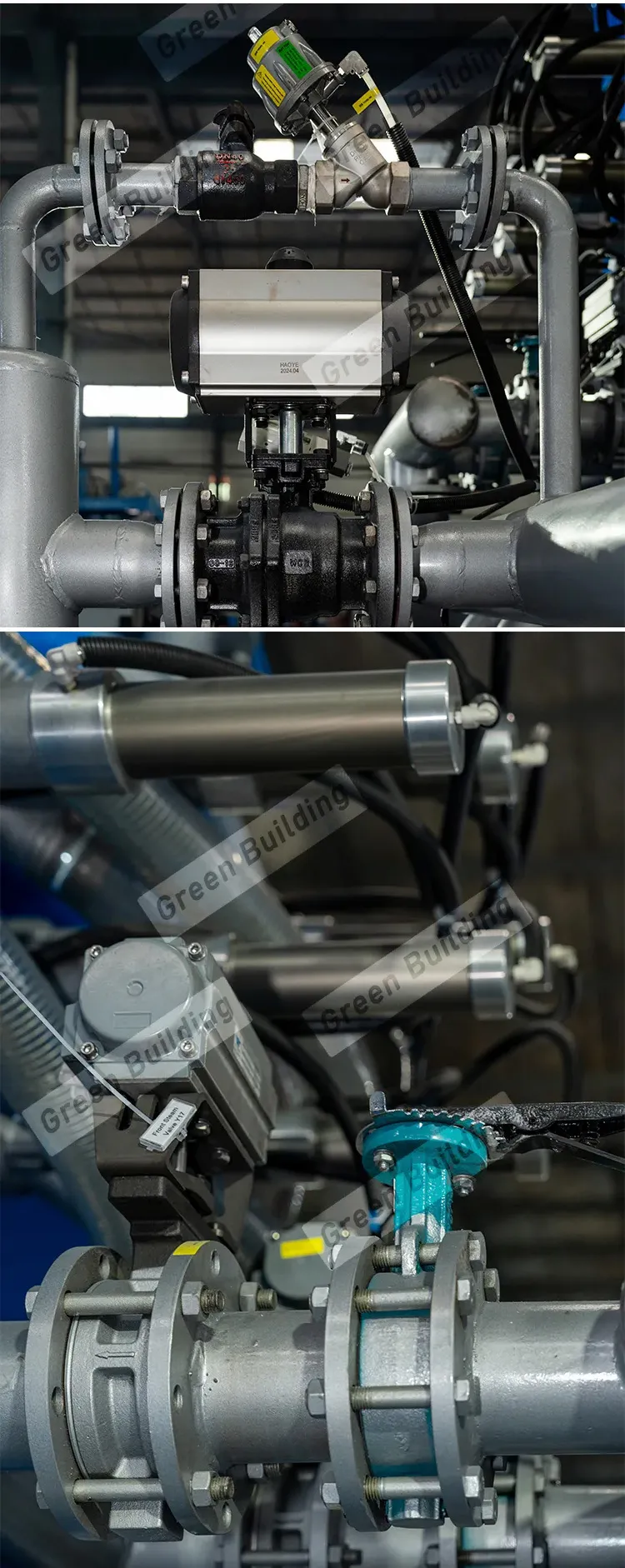

– All electronics are brand Schneider, Pneumatic valves brand Airtec and Burket ,Germany

– Yuken brand hydraulic station controls block ejection, open & close door, lock & unlock door.

– Vacuum and air blower for filling mode & cooling block

– 6 units feeder, settled on back side and side

Block Molding Machine(Vertical)

Block Molding Machine(Vertical)

ping@cngreenindustry.com

Specifications

| Item | Unit | SPB2500VZ |

| Net block Length | mm | 2500/2550 |

| Net block width | mm | 1250/1290 |

| Net block Thickness | mm | 1000/1030 |

| Block density | Kg/m3 | 6-35 |

| Capacity(pcs/h) | 15 kg/m3 | 8-10 blocks/hour |

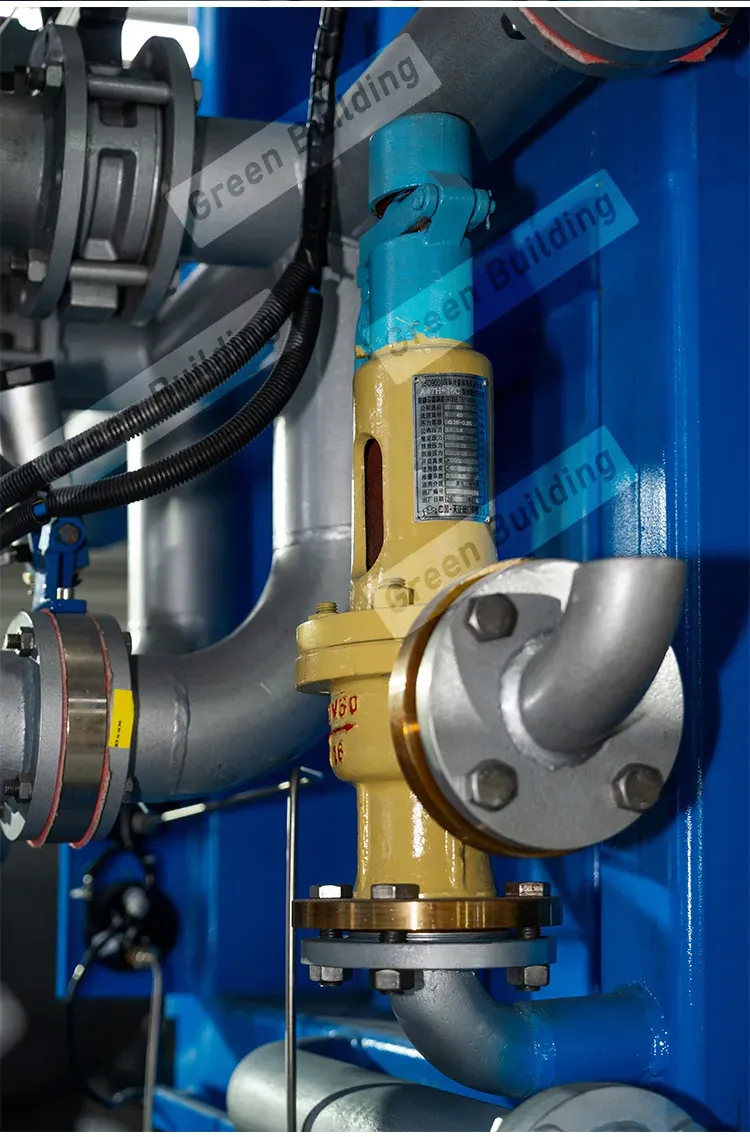

| Steam inlet | mm | 150 |

| Steam consumption | Kg/m3 | 10-20 |

| Steam pressure | Mpa | Above 0.6 |

| Air consumption | M3/cycle | 1 |

| Air pressure | Mpa | Above 0.5 |

| Connect load | Kw | 35.5 |

| Weight | Kg | 10,000 |

Mechanical Characteristics

All procedures are controlled by HMI & PLC, all parameters can be revised in HMI with easy operation

– State standard Q235B Profile steel are used for block mould frame.

– State standard LY12 aluminum is used for steam chamber, thickness 5mm

– All electronics are brand Schneider, Pneumatic valves brand Airtec and Burket ,Germany

– Yuken brand hydraulic station controls block ejection, open & close door, lock & unlock door.

– Vacuum and air blower for filling mode & cooling block

– 6 units feeder, settled on back side and side

– The raw material hopper should be fixed on back of block molding machine by horizontal, equipped level sensor controlled and one unit air blower.When hopper material empty , steam ,air pressure is drop. The machine should alarming , Control by level sensor

Extra device for better production ,which is optional

- Steam reducer DN150 for stable steam for stable steaming

- Germany made Foam pressure sensor control cooling for automatic process.The foam pressure setting can be adjusted in touch screen. Which is more accurate and easy to adjustable.

- Equipped pressure transmitter , all pressure setting can be in the screen. So the machine can pressure can be controlled neither Gauge or digital setting

Product Detail

Leave Your Message

For more information about any of our services, don’t hesitate to get in touch. Our team is always happy to provide information about EPS Industry products.