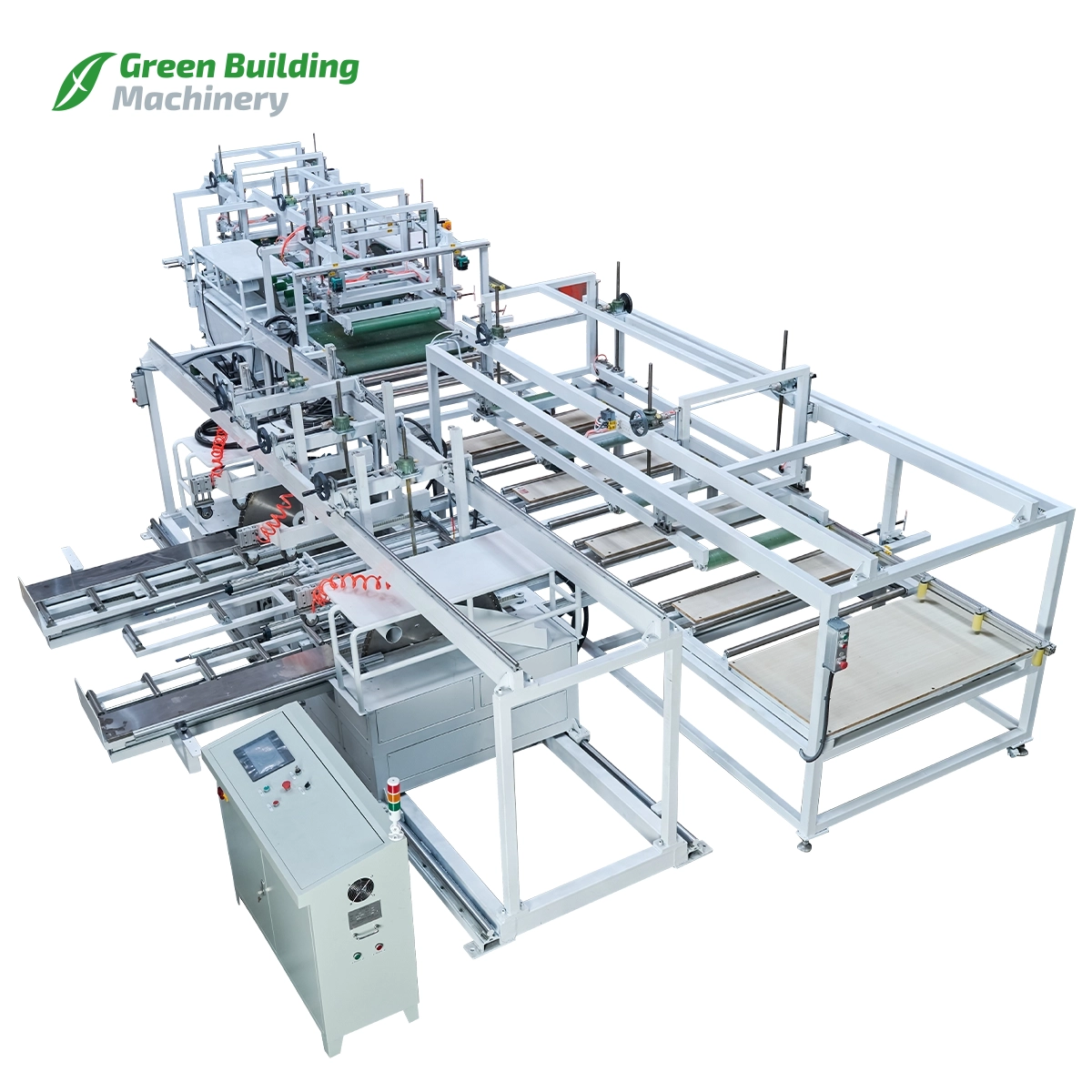

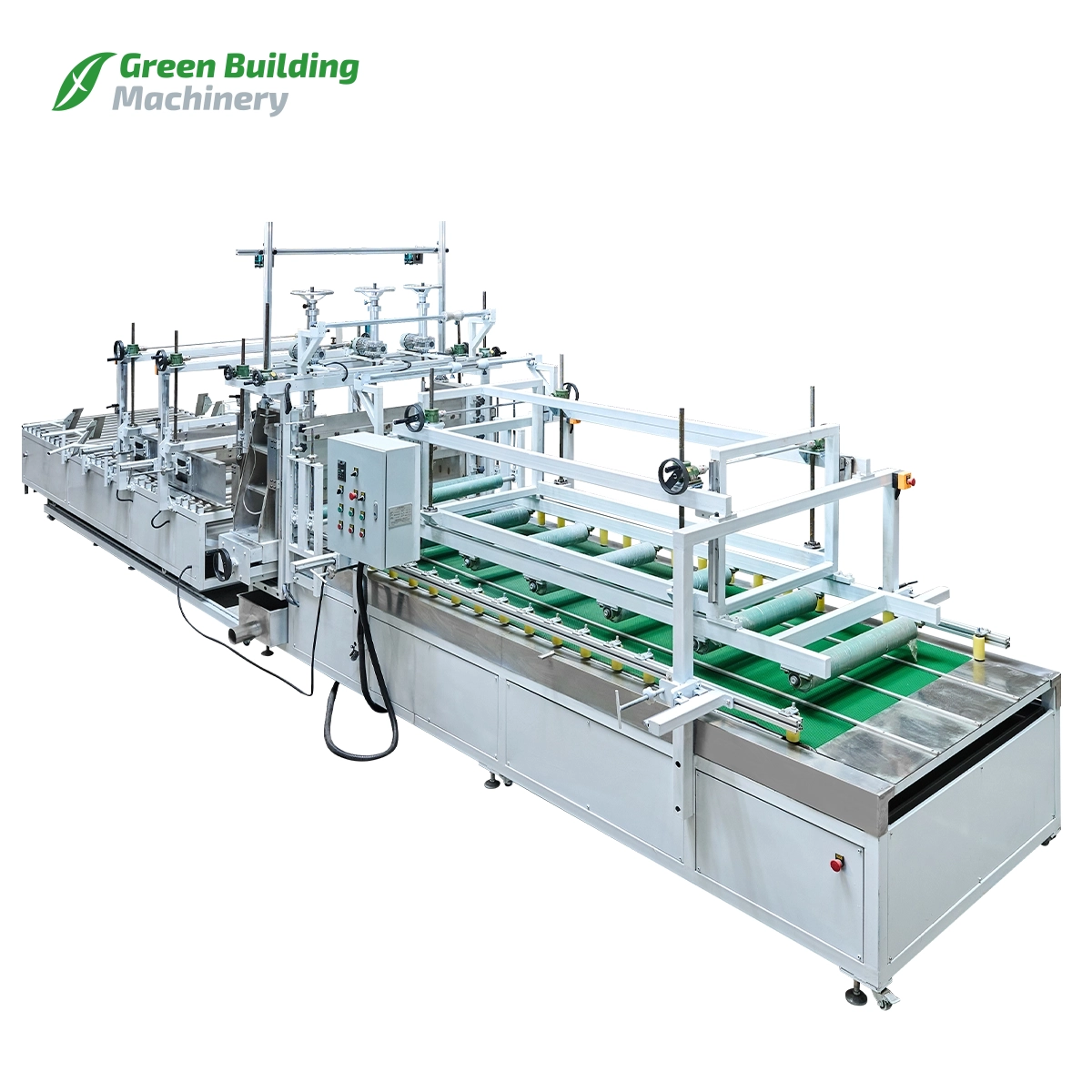

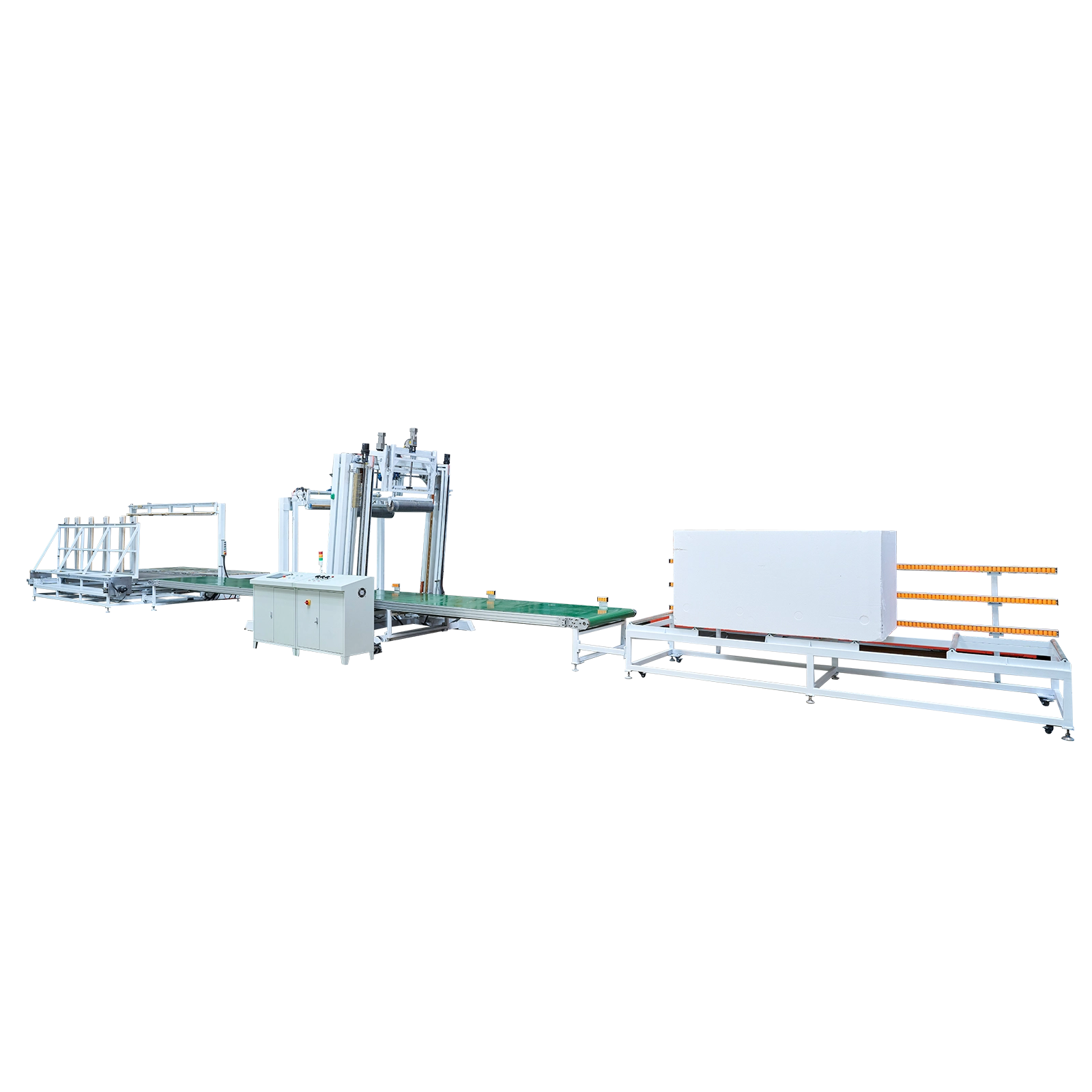

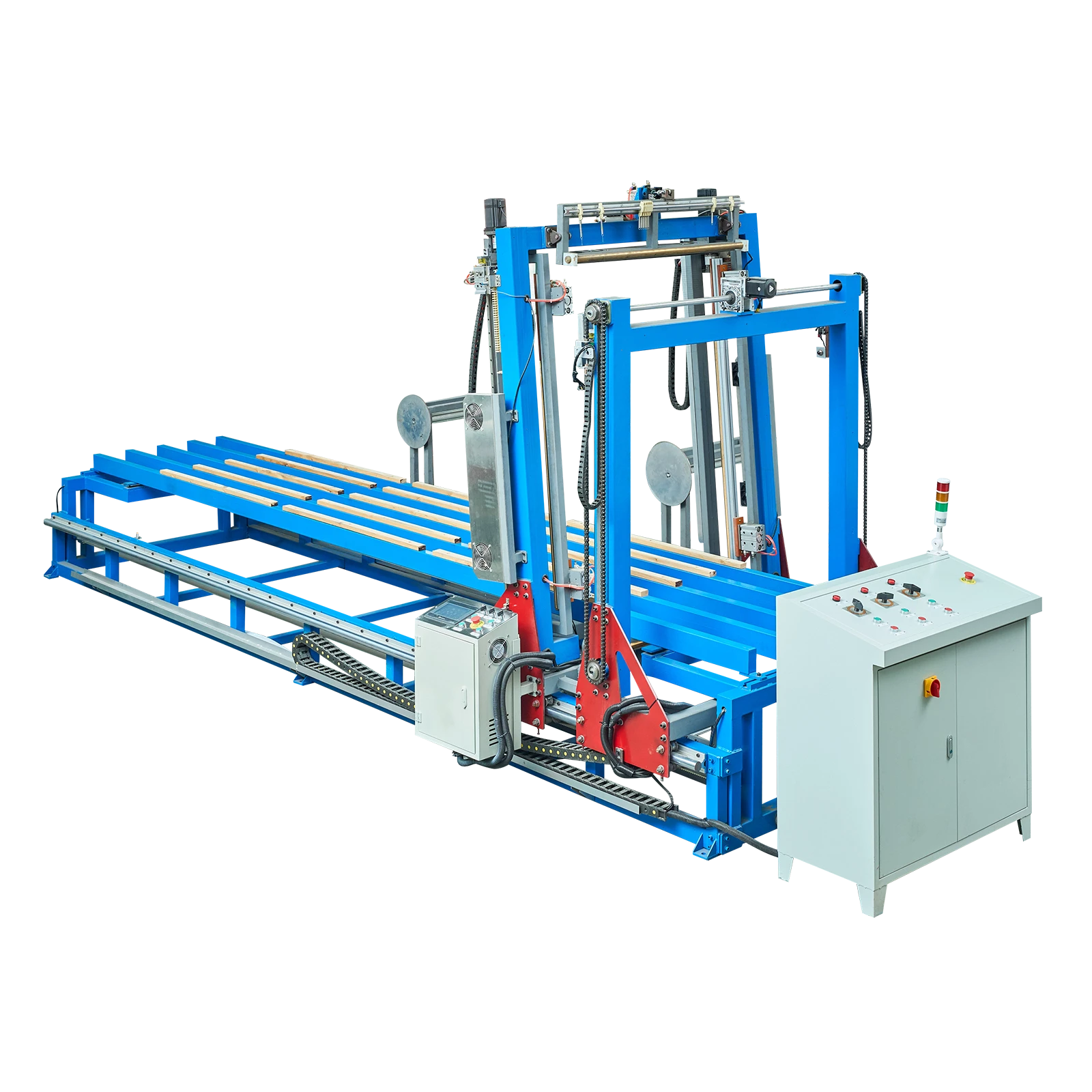

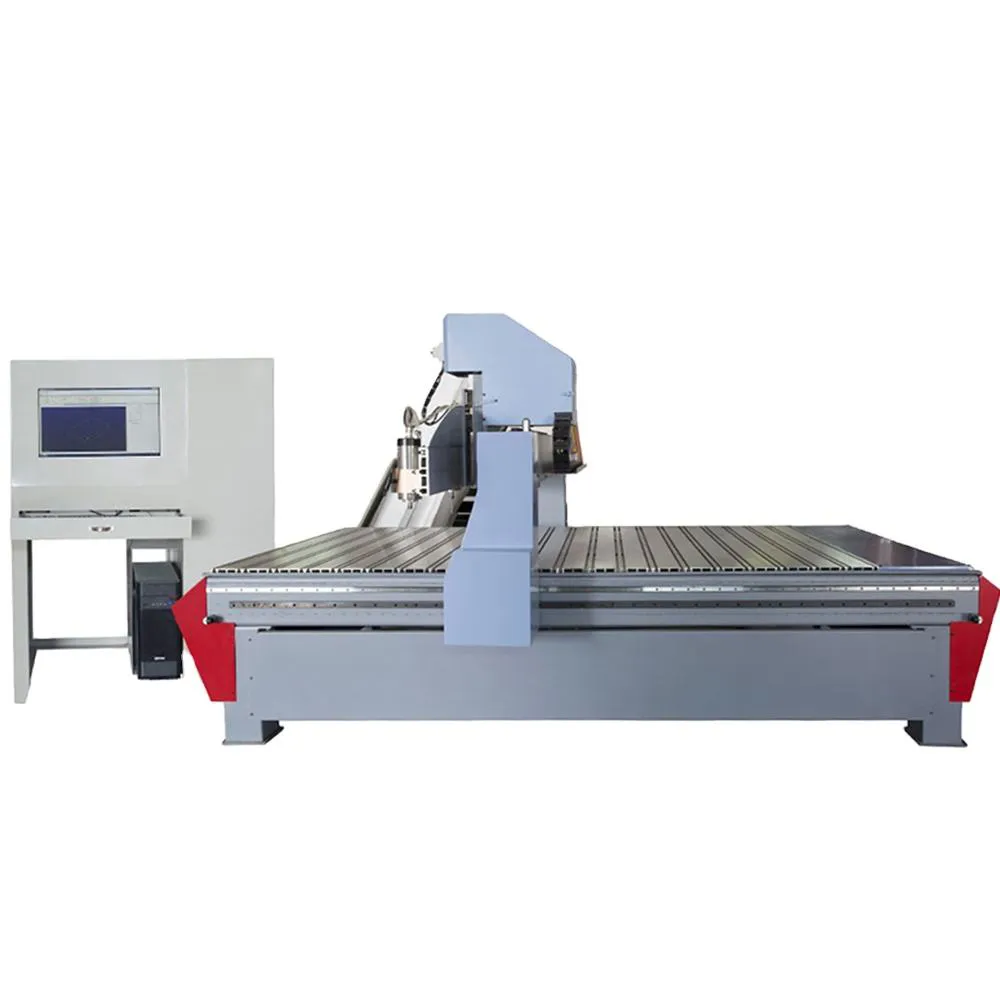

GB-FC series EPS 2D CNC cutting machine is used for cutting various specifications of plastic foam board products, large electric heating cutting machine, foam plastic products factory is the production of large foam plate equipment. This machine can realize linear cutting, cutting; cutting equipment of automobile model, EPC, aviation model, movie props, place raw materials needed to cut.

Main Features:

1,The main frame of the machine is welded by connecting sections and various special connectors. It is stable in movement and high in accuracy;

2,The machine adopts X direction servo motor, Y direction stepper motor drive, smooth movement, free speed regulation, suitable for cutting special graphics, need to constantly change speed requirements, mechanical control accuracy is 0.5mm;

3,Voltage regulation: This machine is equipped with a 15KW transformer, and through electronic voltage regulation, voltage output is 0—220V adjustable. The cutting frame can be installed 15 heating wire, can cut 15 identical patterns or text at the same time

4,This machine adopts touch key input, less operation keys. Simple patterns can also be input directly through the controller. Screen display cutting pattern, tracking cutting function. Adjustable cutting speed, the maximum speed is 4000mm/ minutes. Parameter setting is simple and convenient. At the same time travel device has protection function, when the moving distance beyond the prescribed stroke, automatic the protective stop device.