GB-SPZ1400-1750PT EPS full-automatic foam forming machine adopts PLC and touch screen control, hydraulic movement drive, precise control of the whole process of feeding steam heating, water and vacuum cooling, de-mould and ejection. The equipment considers stable mechanical structure, precise steam heating, and efficient vacuum cooling, greatly improve the molding speed of the equipment and reduce steam consumption. In addition, equipment operability and maintenance safety are also integrated into the design, making this machine the first choice of EPS foam packaging and molding plant.

Eps Moulding Machine

Mechanical Characteristics

- Keep conveyor to remove the productout of machine area. So that the machineleg can be reduced, with double jointing frame, which can keep machine moving very stable at high speed ;

- Keep big hydraulic pump, 1lkw, instead of 7.5kw,Plus big flow pump.Which can keepmachine moving faster. Can be reach 260mm/s. Which will save 3-4 S cycle time ;

- A.Big hydraulic motor+strong machine body for stable and fast movement ;

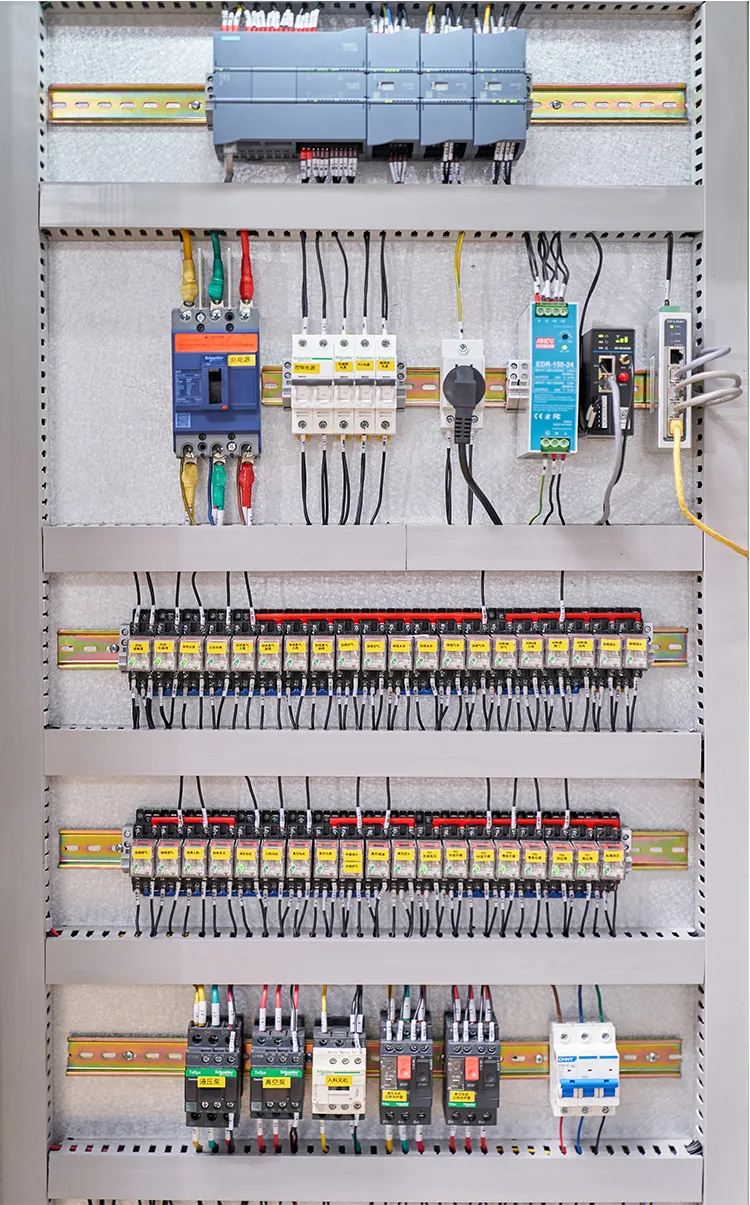

- B.We set control box in the ground, Keep platform around and top for easy maintenance.

Controller And Software

- The machine equipped DN100 Japan Steam reducer. Equipped DN65-DN80 steam for each side ;

- USD SMC PID+Balance valve for proportional steam pressure adjustment. Which will give very stable. Fast and Accurate steaming. It is key for production, which save you energy and cycle time ;

- A.Big steam flow, accurate,stable and fast steaming ;

- B.High efficiency Vacuum system. This machine equipped very efficiency tank with water spray on the top. Plus one more S.S heat exchange inside, Double cooling will compact hot vapour rate, The vacuum efficiency will be increased obviously ;

- C.All pressure setting will be done in the screen, By SMC digital PID valve control de-mould, filling and steaming, instead of Mechanical manual valve

Main Technical Parameters

| ITEM | UNIT | SPZ1400PT | PSZ1600PT | SZ1750PT |

| Steam Reducer | Gp1000 | Dn80 | Dn100 | Dn100 |

| Hydraulic Pressure | T | 25T | 40T | 40T |

| Mould size | mm | 1400*1200 | 1600*1350 | 1750*1500 |

| Window Size | mm | 1250X1050 | 1500*1200 | 1600*1300 |

| MaxProductSize | mm | 1200X1000 | 1450×1150 | 1550×1250 |

| Max Product Height | mm | 330 | 330 | 330 |

| Guide Rod Size | mm | φ85 | φ85 | φ10 |

| Hydraulic Cylinder | mm | φ140 | φ120 | φ120 |

| Qty OfCylinder | pcs | 1 | 2 | 2 |

| MaterialHopper | Liter | 300L | 500L | 550L |

| Outlet Of Hopper | pCs | 22*2 | 22*2 | 25*2 |

| Main Steam Inlet | Inch | 3″ | 4” | 4” |

| Cooling Water Inlet | Inch | 3” | 3” | 3” |

| AirInlet | Inch | 2” | 11/2 | 2” |

| Drainage Outlet | Inch | 6” | 6” | 6” |

| Hydraulic Pump | KW | 7.5 | 11 | 11 |

| Vacuum Pump | KW | 5.5 | 7.5 | 7.5 |

Product Detail

Leave Your Message

For more information about any of our services, don’t hesitate to get in touch. Our team is always happy to provide information about EPS Industry products.