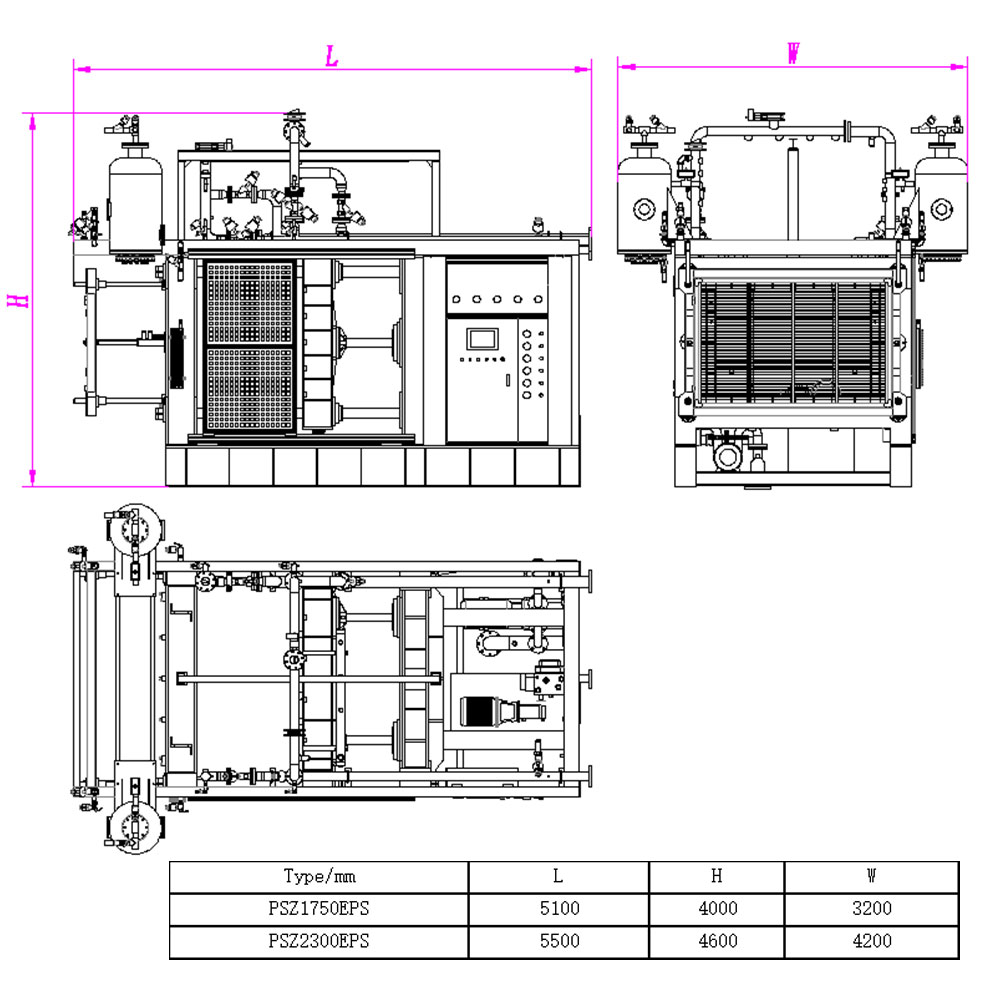

CHARATER:

1. All templates are welded from high-strength steel plates, processed by high temperature annealing, heat treatment; surface de-rusted by sandblast and coated by zinc, sprayed by anti-rust paint, ensured highest stability

2. The machine adopts GP1000 steam reducer , SPZ2300: DN80+DN32 (cylinder valve ,PID control). electrical PID Pressure setting for accurate steaming

3. all pipe ,flange connection and machine leg base are hot Zink coating

4. sealing system- all fast plug are closely sealed with liquid sealant, and the PU pipes are replaced by nylon tubes,prolonged service life,and saves energy with little air leakage.

5. Equipped with double barrel and able to produce eps products of 2 different density meanwhile; delicate design with the barrel makes for excellent pressure-preservation function. All outlets have fast copper connectors.

6. Add PID control for filling guns blowing air and pressure fillings

7. add Electrical host and S.s product tray

8. set protection system for suddenly power off, and inter-middle restart process.

9. set water cooling for hydraulic tank.