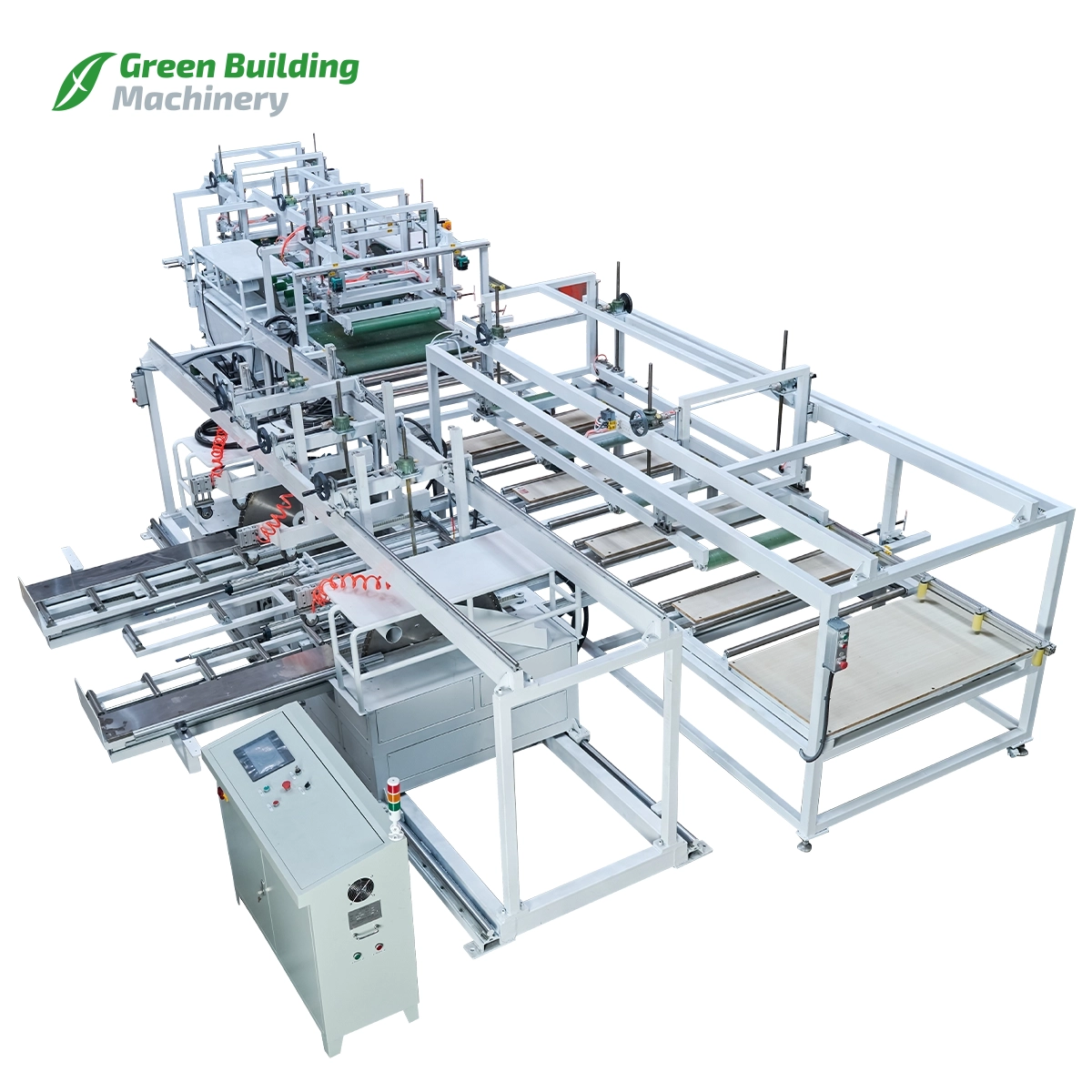

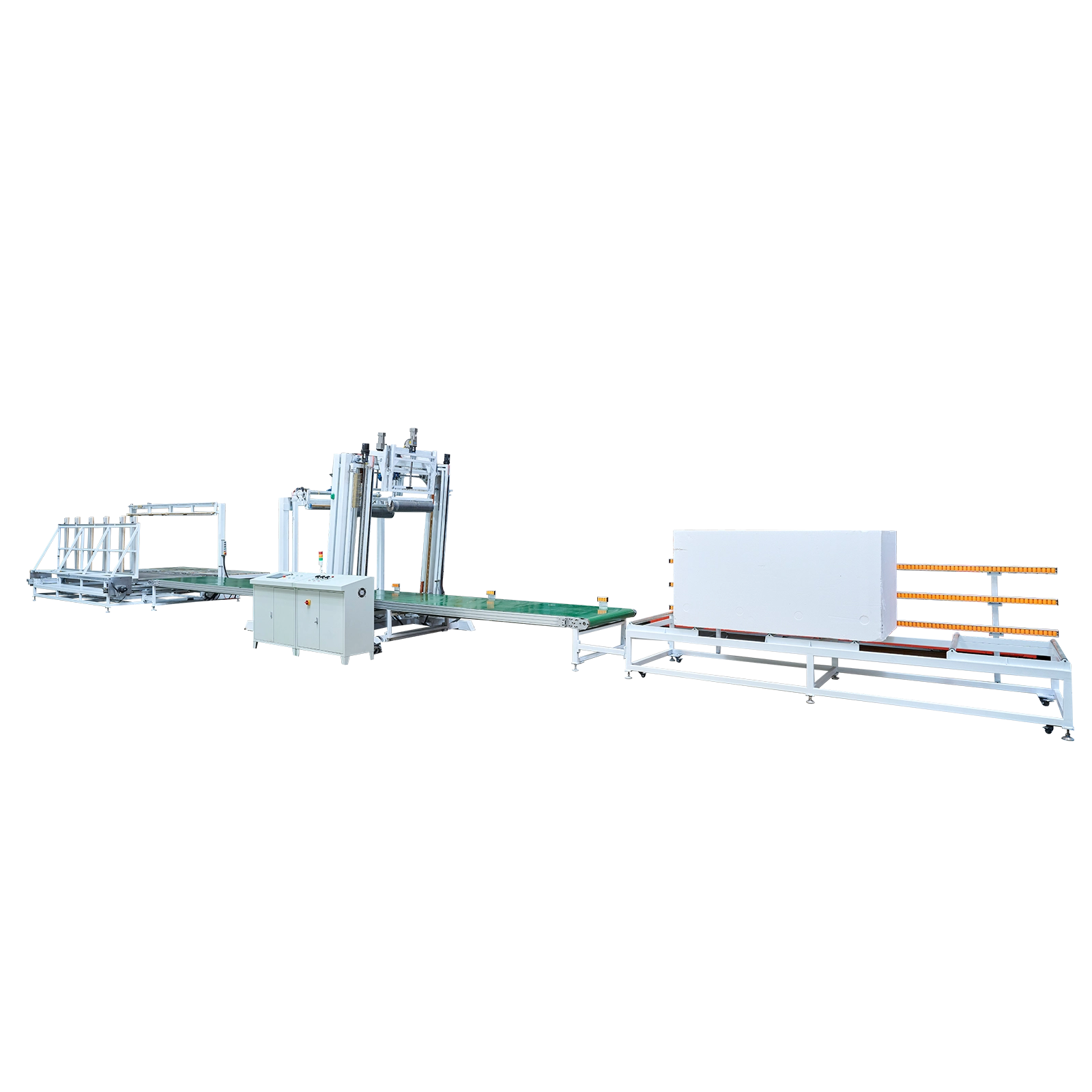

GB-SPC200~600-3C series EPS cutting machine is a continuous, fully automatic foam sheet cutting machine controlled by PLC and HMI. This machine use conveyor to move Block and equipped the fixed cutting frame to perform horizontal, vertical, and sectional cutting of EPS foam block , offering cutting in three consecutive directions with multiple cutting wires, fast cutting speed, and high automation. It is a essential equipment for large and medium-sized EPS Block factory

Fully automatic continuous foam cutting machine with vibration cutting and automatic wire setting

Fully automatic continuous foam cutting machine with vibration cutting and automatic wire setting

ping@cngreenindustry.com

Specifications

| GB-SPC200-3C | GB-SPC400-3C | GB-SPC600-3C |

| 2000x1300x1300 | 4000x1300x1300 | 6000x1300x1300 |

| Item | UNIT | PARAMETER | ||

| Suitable for block size | mm | 2000-6000*1300*1300 | ||

| Min. Cutting thickness | mm | 15 | Auto wire setting in horizontal | yes |

| Cutting speed | m/min | 0.5-1.5 | Manually wire set in Vertical cut | yes |

| Max. Wires in horizontal | piece | 50 | Cross cutting wire set manually | yes |

| Max. Wires in vertical cutting | piece | 15 | Vibration wire cutting for horizontal | yes |

| Hot wire specification | mm | 0.4-0.8 | Vibration wire cutting for vertical | yes |

| Total Installed Power | Kw | 24.8 | ||

| Gross Weight | Kg | 3500/ 4 meter cutter | Specification:

Belt conveyor for movement Capacity : 5-7 blocks per hour for 4 meter block. |

|

| Overall size | MM | 12000-26000 *4500*2420 |

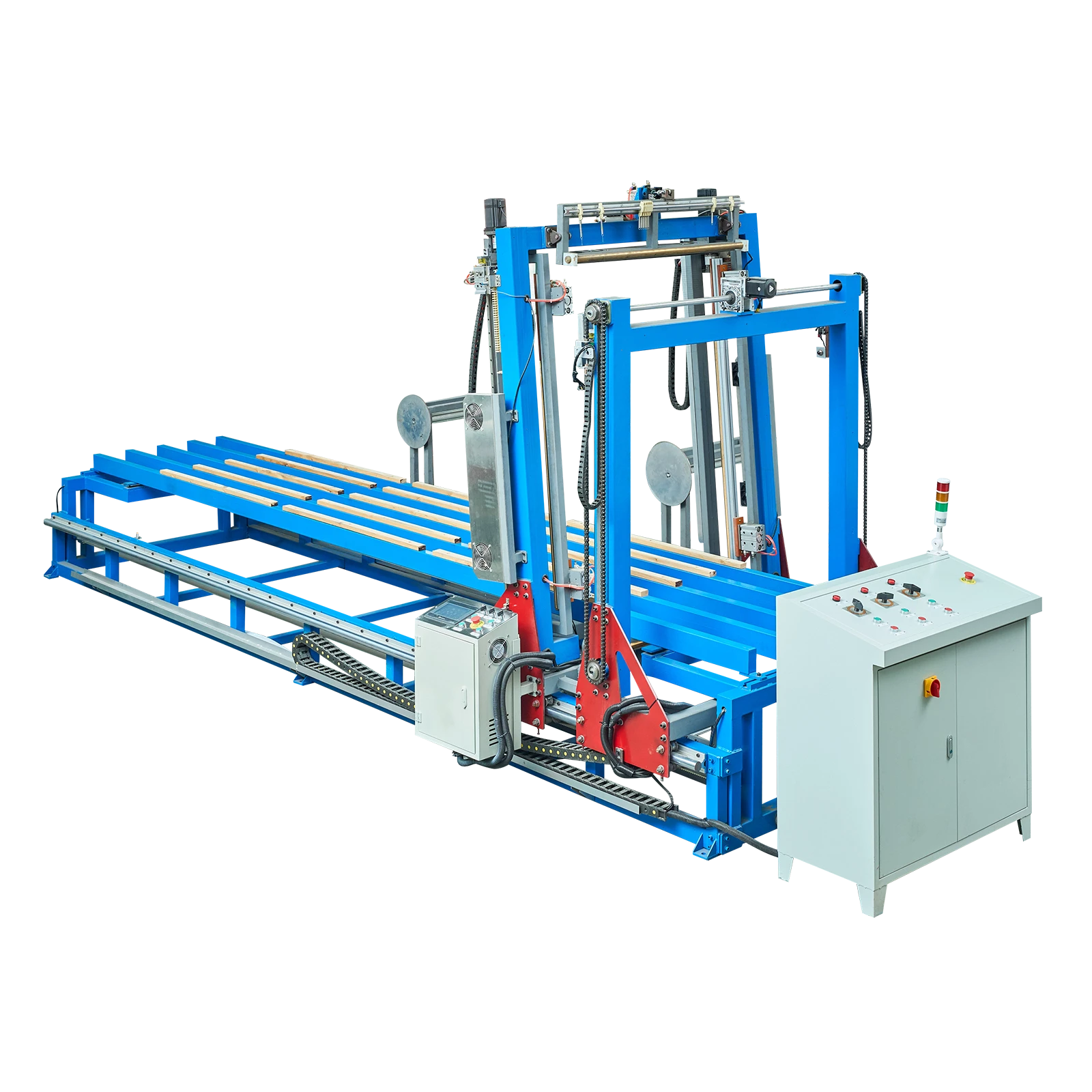

Mechanical Characteristics

- The machine is controlled by PLC and touch screen, allowing for fully automatic or manual operation.

- The horizontal, vertical, and sectional cutting voltages are controlled by three sets of transformers and rotary switches, offering a wide range, more cutting wires with stable output.

- The cutting speeds for horizontal, vertical, and sectional cutting are adjusted through frequency converters. Additionally, with the EPS blockmoving and the cutting frame fixed, it accommodates cutting sheet of various densities with high precision.

- The horizontal cutting wiresare automatically set by the servo motor and PLC control, with the vertical and sectional cutting lines pre-hung and equipped with rulers for simple setup. Once the steel wires are set, the cylinder will tighten them.

- The cutting speed increases by 30% when vibratory cutting is activated for horizontal and vertical cutting.

- Powerful fans cool the electrical wires on both the horizontal and vertical sides.

- Pause buttons are located at multiple points, along with emergency stop buttons for use in any emergency situation

Product Detail

Leave Your Message

For more information about any of our services, don’t hesitate to get in touch. Our team is always happy to provide information about EPS Industry products.